Not all CNC machines are created equal. Two of the most common methods, Swiss CNC and Traditional CNC, each have unique strengths that make them better suited for certain projects. At Topcraft Precision, we carefully evaluate every job to determine which approach will deliver the best results. So, what sets these two methods apart, and when should you use one over the other? Let’s break it down.

How Swiss CNC and Traditional CNC Work

Traditional CNC Machining

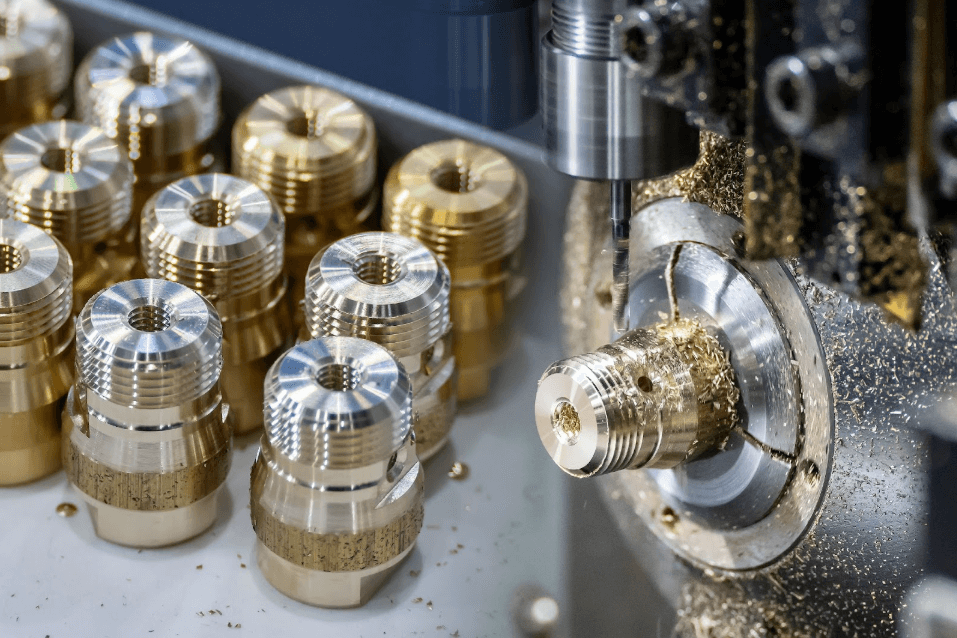

Traditional CNC machines, like mills and lathes, are workhorses in manufacturing. They hold the workpiece in place while cutting tools shape it from different angles. These machines excel at handling larger parts, complex geometries, and a wide variety of materials. Because they’re highly adaptable, they’re often the go-to choice for prototyping, mid-volume production, and parts that don’t require extreme tolerances.

Swiss CNC Machining

Swiss CNC machines, originally developed for the watchmaking industry, take a different approach. Instead of fixing the workpiece in place, Swiss machines guide the material through a sliding headstock while cutting tools work on it. This design provides exceptional stability, reducing vibration and allowing for incredibly tight tolerances—even on tiny, delicate parts. Swiss CNC shines when working with long, slender components or high-volume production runs where consistency is key.

Key Differences Between Swiss and Traditional CNC

1. Part Size & Complexity

- Swiss CNC is ideal for small, intricate parts, especially those with diameters under 1.5 inch. Think medical pins, micro screws, or electronic connectors.

- Traditional CNC handles larger parts and more varied shapes, making it better for engine components, brackets, or housings.

2. Production Volume

- Swiss CNC is built for efficiency in long production runs. Once set up, it can produce thousands of identical parts with minimal variation.

- Traditional CNC is more flexible for shorter runs or frequent design changes

3. Material Usage & Waste

- Swiss CNC minimizes material waste because the bar stock feeds continuously, reducing excess scrap.

- Traditional CNC may generate more waste, especially when machining larger blocks of material.

4. Tolerances & Surface Finish

- Swiss CNC achieves tighter tolerances and smoother finishes due to reduced tool pressure and vibration.

- Traditional CNC can still produce high-quality finishes but may require additional post-processing for ultra-fine details.

When to Choose Swiss CNC vs. Traditional CNC

Go with Swiss CNC if…

- You need a part with a 1.5 diameter or under.

- Your project involves high-volume production.

- Tight tolerances and fine details are non-negotiable.

- You’re working with materials prone to deflection, like titanium or stainless steel.

Opt for Traditional CNC if…

- Your parts are larger or require complex multi-axis machining.

- You need flexibility for prototypes or low-volume batches.

- The design may change frequently during production.

- The part geometry doesn’t benefit from Swiss machining’s sliding headstock.

How Topcraft Precision Chooses the Right Process

At Topcraft, we don’t believe in a one-size-fits-all approach. Instead, we analyze each project’s requirements (size, material, volume and tolerances) before deciding which method makes the most sense. Our team has years of experience with both Swiss and Traditional CNC, so we know how to maximize efficiency without sacrificing quality. Whether you need micro-machined components or larger industrial parts, we’ll guide you toward the best solution.

Final Thoughts

Both Swiss CNC and Traditional CNC have their place in manufacturing, and the right choice depends entirely on the job. Swiss CNC offers unbeatable precision for tiny, high-volume parts, while Traditional CNC provides versatility for larger or more varied components. At Topcraft Precision, we’re here to help you navigate these options and deliver parts that meet your exact needs.

Have a project in mind? Let’s discuss which machining method is right for you.