Robotic CNC

Zero Defect Technology

Commitment to Customers

Our first priority to our customers is to utilize our intellectual properties, design and develop the proper manufacturing methodologies that give quality and cost effective solutions while working together in a healthy, partnering manner.

Cost Effective Solutions

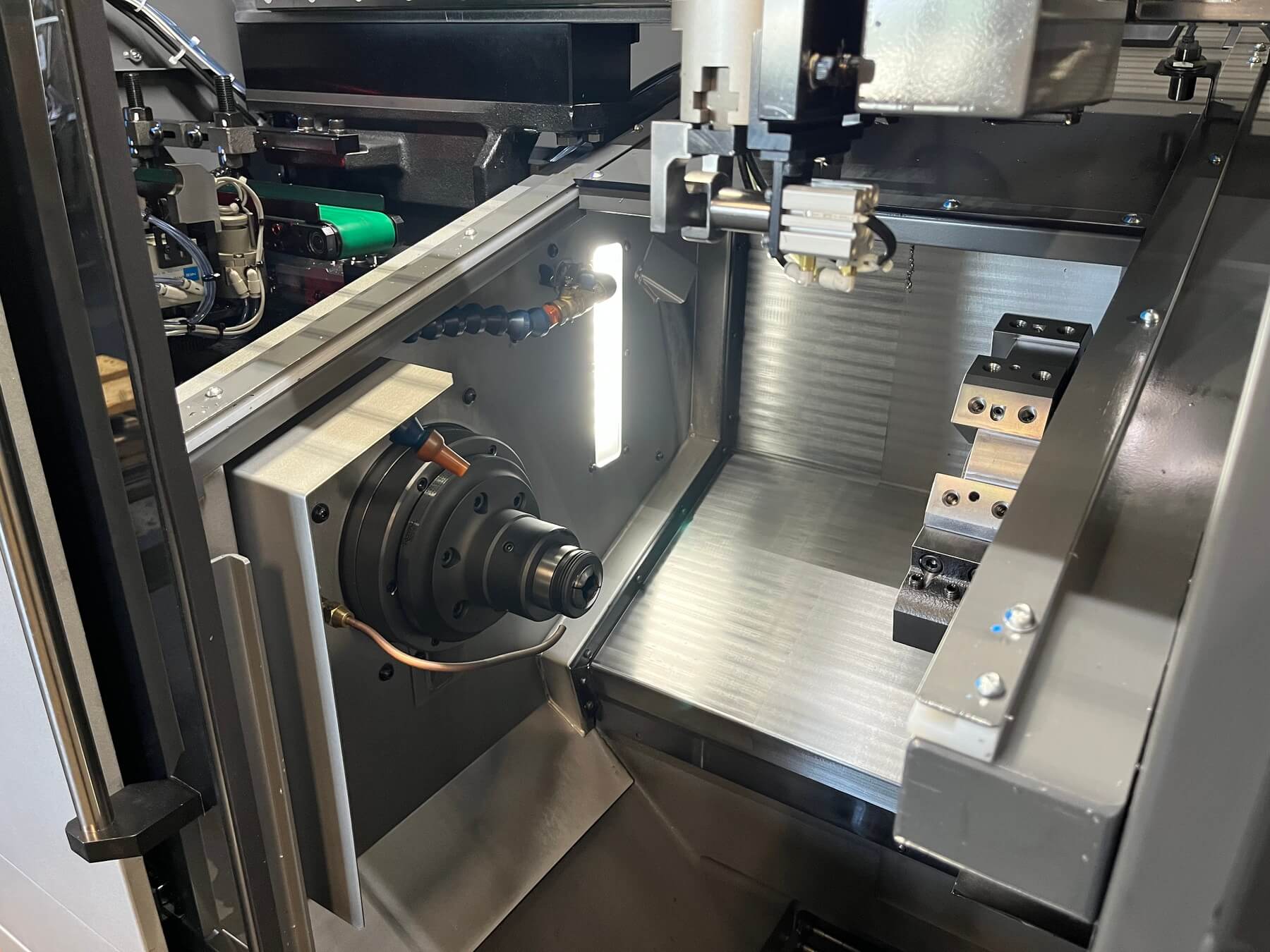

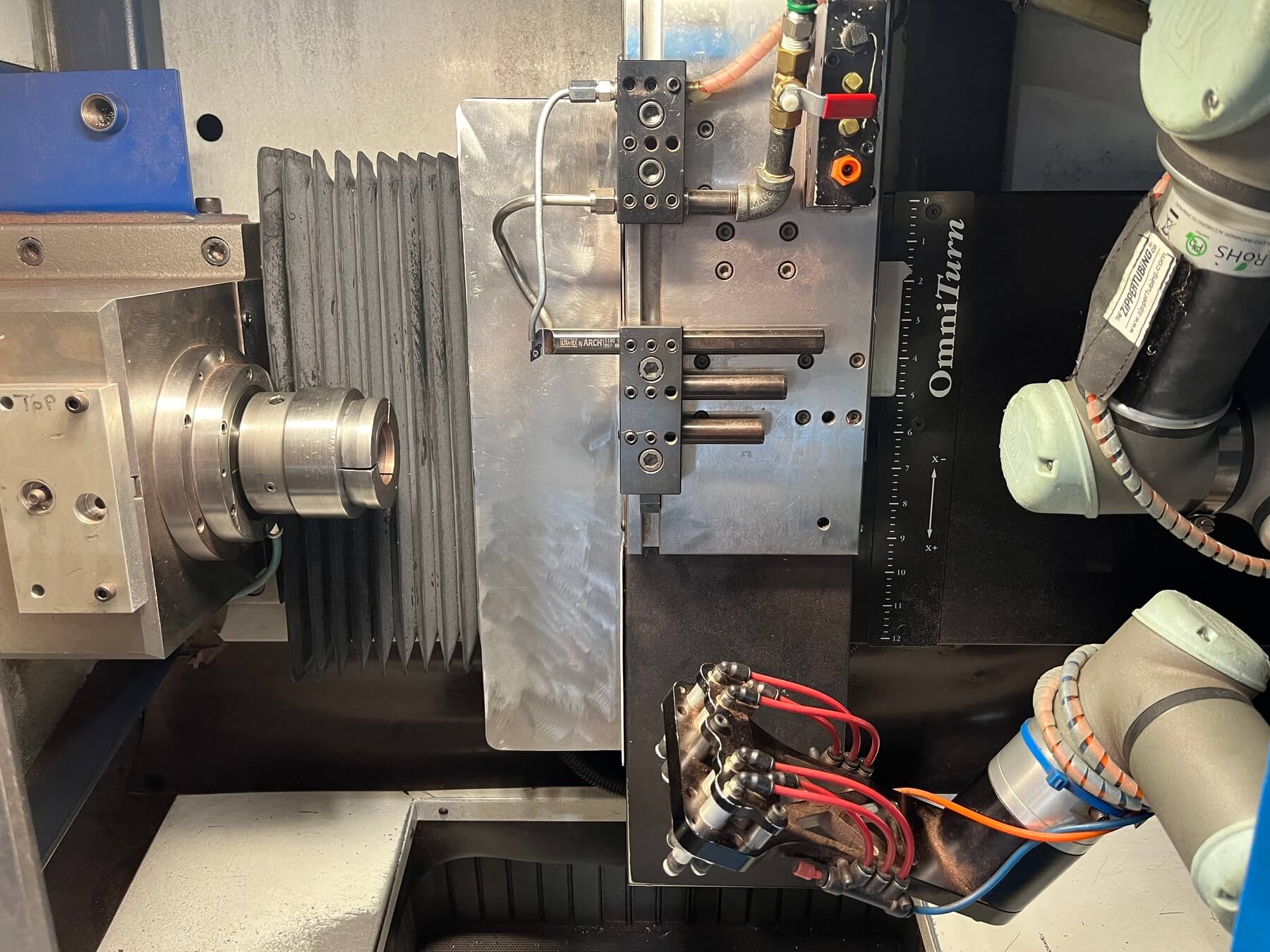

Robotics

What we Offer

The use of robotic arms is beneficial on mid to large volume programs. Currently, Topcraft utilizes robotics on multiple programs with annual volumes ranging between 100,000pcs to 1,500,000pcs.

Topcraft’s customers benefit by receiving an effective cost option, a high-quality part, and repeatable output when robotic work arms are utilized.

Topcraft is currently tending four CNC spindles with robotic work arms. Two of these robotic arms are Universal, collaborative robots, allowing machinists to closely interact with the robots. Two of these robotic arms are build into the machining center. In both scenarios the CNC turning center and the robotic arm communicate with one another.

Our Customers'

Testimonials

"We have been using Topcraft as a critical supplier for more than 12 years. They provide excellent quality precision machined parts. Communication and responsiveness is excellent on the rare occasion of any issues."