In component manufacturing, the difference between a perfect fit and a costly mistake often comes down to tiny measurements, sometimes as small as a fraction of a human hair. These measurements (called tolerances) define how much a part can deviate from its ideal dimensions and still function correctly. Get them right, and everything slides together smoothly. Get them wrong, and …

What Is a CNC Screw Machine and How Does It Work?

At Topcraft Precision, we know that creating identical parts in large quantities requires the right tools. That’s where CNC screw machines come in – these specialized machines have become essential for manufacturers who need to produce thousands of uniform components without sacrificing quality. But what exactly makes these machines so valuable? Let’s take a closer look at how they work …

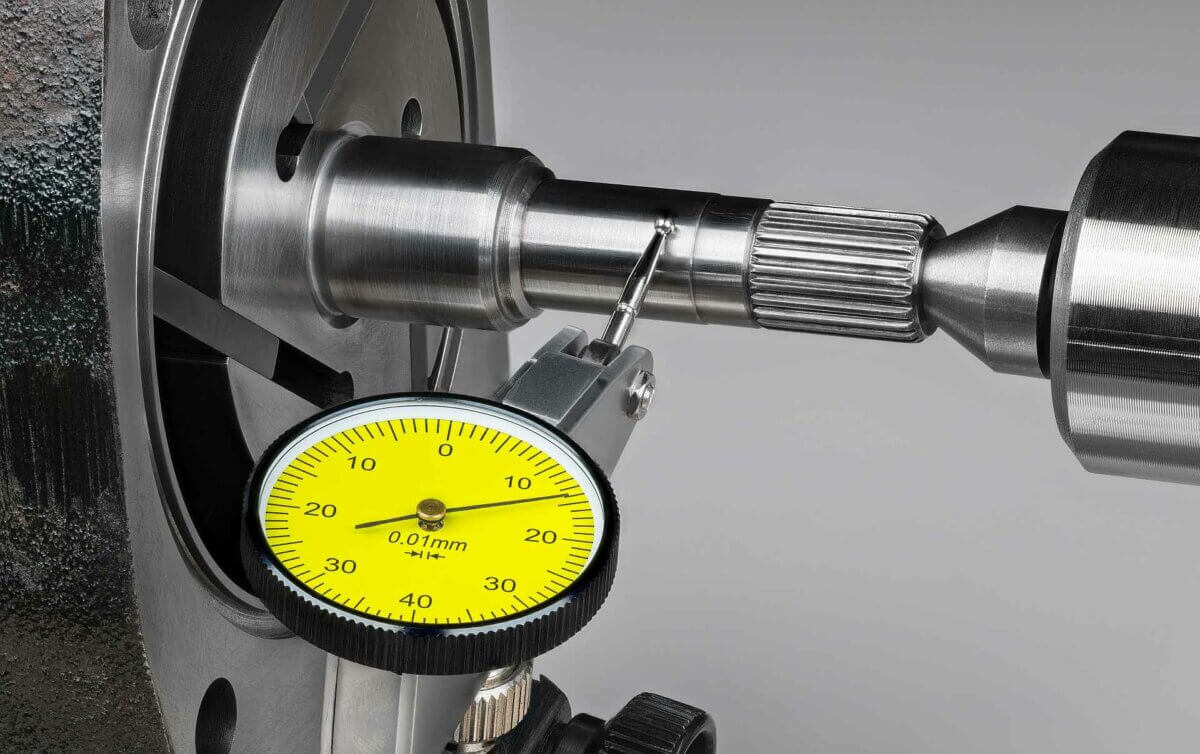

Why Micrometer Readability Matters in Precision Work

At Topcraft Precision, we know that a fraction of a millimeter can mean the difference between a perfect part and costly rework. Micrometer readability isn’t just a detail—it’s the way to get dependable measurements in machining and inspection. When micrometers are misread–even by a tiny margin–the consequences add up quickly. Out-of-spec parts may slip through, assemblies won’t fit, and entire …

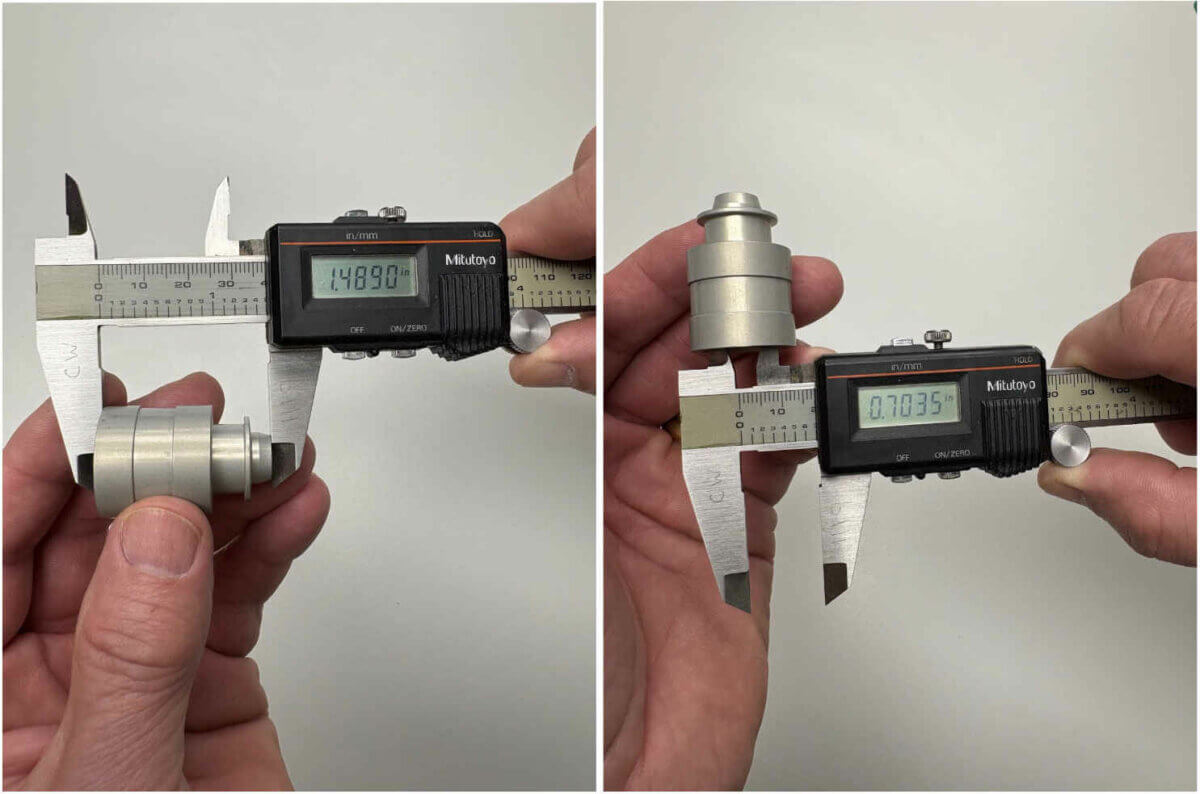

How Caliper Accuracy Impacts Precision Machining

Why Calipers Matter in Machining A caliper is a machinist’s best friend when it comes to checking dimensions. Whether digital, dial, or vernier, a well-maintained caliper helps confirm that every cut, bore, and thread meets specifications. Even the smallest deviation can throw off a part’s fit and function, leading to wasted time, materials, and unhappy customers. At Topcraft, we rely …