Blogs

Feb. 05, 2026

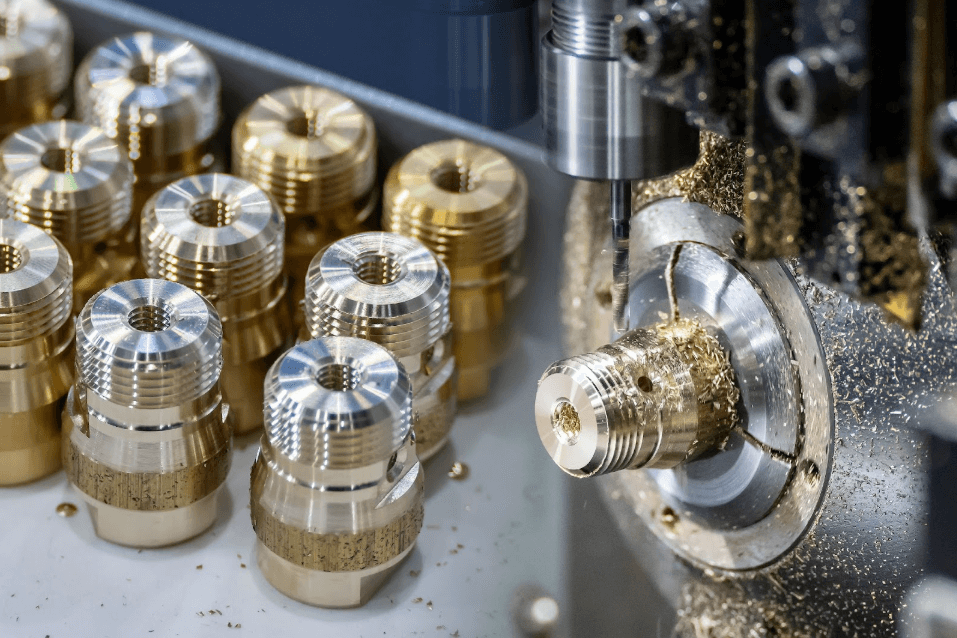

Why Workholding Is Key to Machining Accuracy

Think about the last part you ran that didn’t meet spec. Was it a dimension out of tolerance, a finish that wasn’t right or chatter marks you couldn’t eliminate? Before you blame the toolpath or the spindle, there’s an important question to ask. Was the part held correctly? The Silent Foundation of Every Operation At Topcraft Precision, we’ve learned one

Dec. 29, 2025

A New Era of Possibility – Welcoming the Citizen Cincom L32 to Topcraft Precision

We are excited to announce a major upgrade to our shop: the new Citizen Cincom L32 Swiss-type CNC lathe. This machine expands our capabilities by allowing us to take on more complex projects and provide better value for our partners. The new L32 lathe directly addresses our customers’ changing needs, allowing us to produce a broader variety of parts more

Nov. 24, 2025

The Precision Components Inside a Modern Combine – More Than Meets the Eye

If you’ve ever watched a combine harvester roll through a field, turning standing grain into a harvested crop, you’ve witnessed a small miracle of modern manufacturing. These machines are behemoths of efficiency, but their true complexity is hidden beneath the sheet metal. It’s a complexity built on thousands of individual parts working in perfect harmony. So, how many parts are

Nov. 03, 2025

Swiss CNC vs. Traditional CNC: What’s the Difference?

Not all CNC machines are created equal. Two of the most common methods, Swiss CNC and Traditional CNC, each have unique strengths that make them better suited for certain projects. At Topcraft Precision, we carefully evaluate every job to determine which approach will deliver the best results. So, what sets these two methods apart, and when should you use one

Oct. 14, 2025

Synergizing Manufacturing: How Machining and Casting Work Together for Superior Parts

The best manufacturing outcomes typically come from combining processes rather than choosing between them. While precision machining and casting each have distinct strengths, combining them unlocks new possibilities for manufacturers in terms of quality, efficiency and performance. In this blog, we’ll cover how machining and casting complement each other, why hybrid manufacturing delivers the best results and how Topcraft uses

Sep. 17, 2025

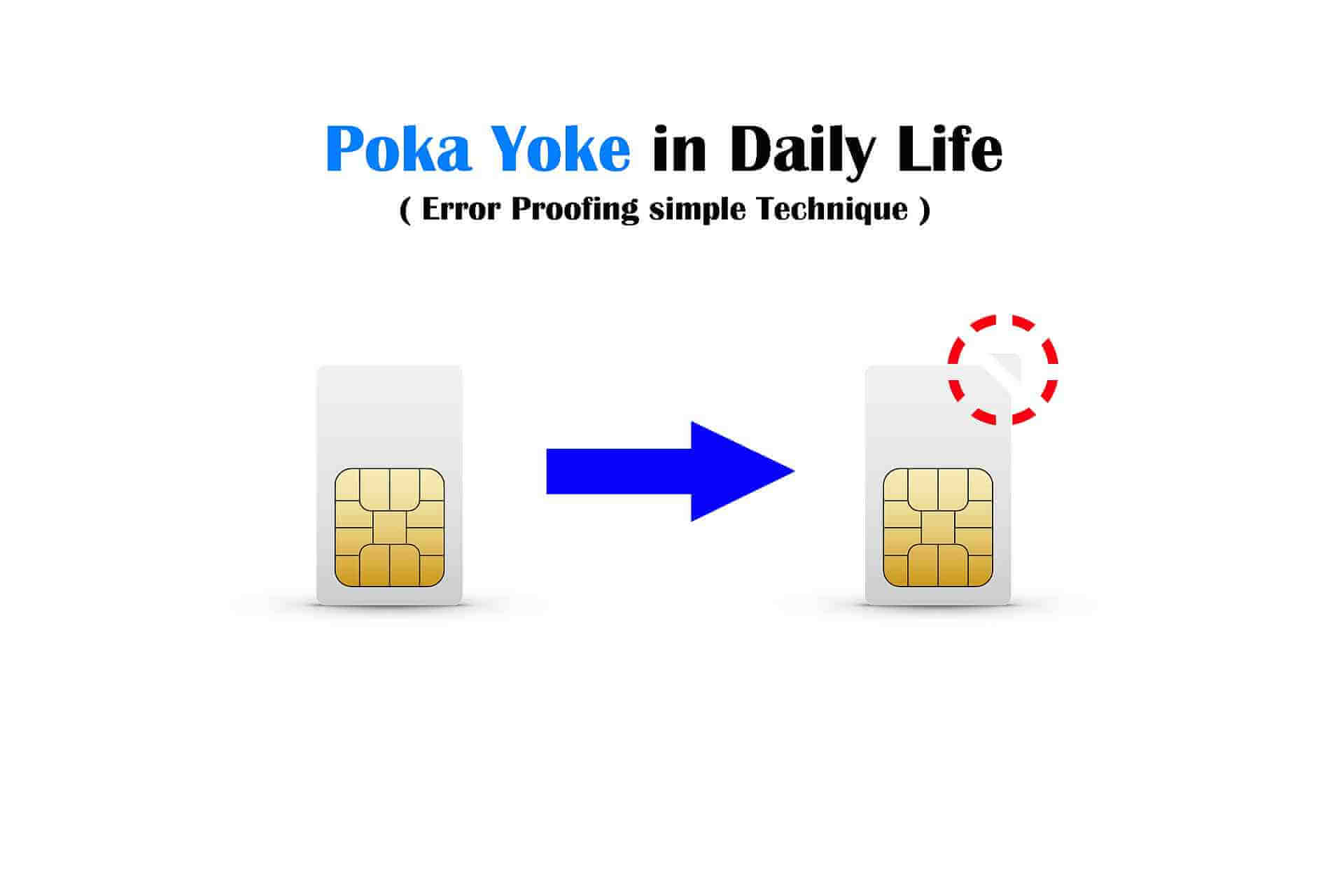

Real-World Poka-Yoke Examples in Precision Manufacturing

At Topcraft Precision, we make sure the parts we make are right the first time. That’s where poka-yoke (mistake-proofing) comes in. From simple jigs to sophisticated software checks, poka-yoke takes many forms in machining, and we use them all to keep defects at bay. In this blog, we’ll explore real-world poka-yoke applications in precision manufacturing, share case studies from our

Aug. 21, 2025

How to Choose a Partner for High Precision Machining

When your project demands tight tolerances and flawless execution, the right high precision machining partner can mean the difference between success and costly setbacks. Not every shop can deliver the level of detail and consistency needed for specialized components, so how do you separate the best from the rest? In this guide, we’ll walk through what to look for in

Jul. 07, 2025

Why Tolerances Matter in Component Manufacturing

In component manufacturing, the difference between a perfect fit and a costly mistake often comes down to tiny measurements, sometimes as small as a fraction of a human hair. These measurements (called tolerances) define how much a part can deviate from its ideal dimensions and still function correctly. Get them right, and everything slides together smoothly. Get them wrong, and

Jun. 19, 2025

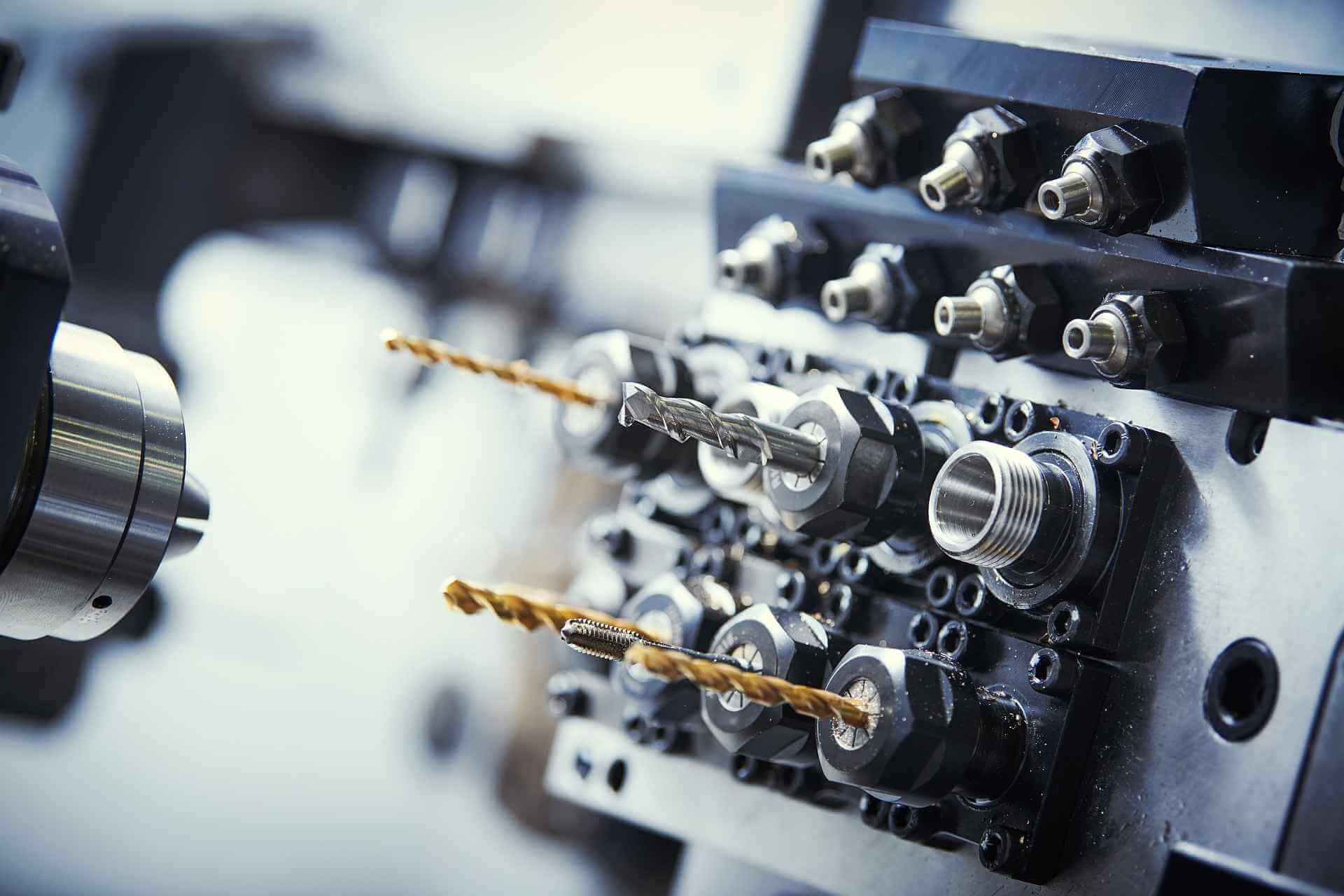

What Is a CNC Screw Machine and How Does It Work?

At Topcraft Precision, we know that creating identical parts in large quantities requires the right tools. That’s where CNC screw machines come in – these specialized machines have become essential for manufacturers who need to produce thousands of uniform components without sacrificing quality. But what exactly makes these machines so valuable? Let’s take a closer look at how they work

May. 22, 2025

Why Micrometer Readability Matters in Precision Work

At Topcraft Precision, we know that a fraction of a millimeter can mean the difference between a perfect part and costly rework. Micrometer readability isn’t just a detail, but the way to get dependable measurements in machining and inspection. When micrometers are misread (even by a tiny margin) the consequences add up quickly. Out-of-spec parts may slip through, assemblies won’t

Apr. 25, 2025

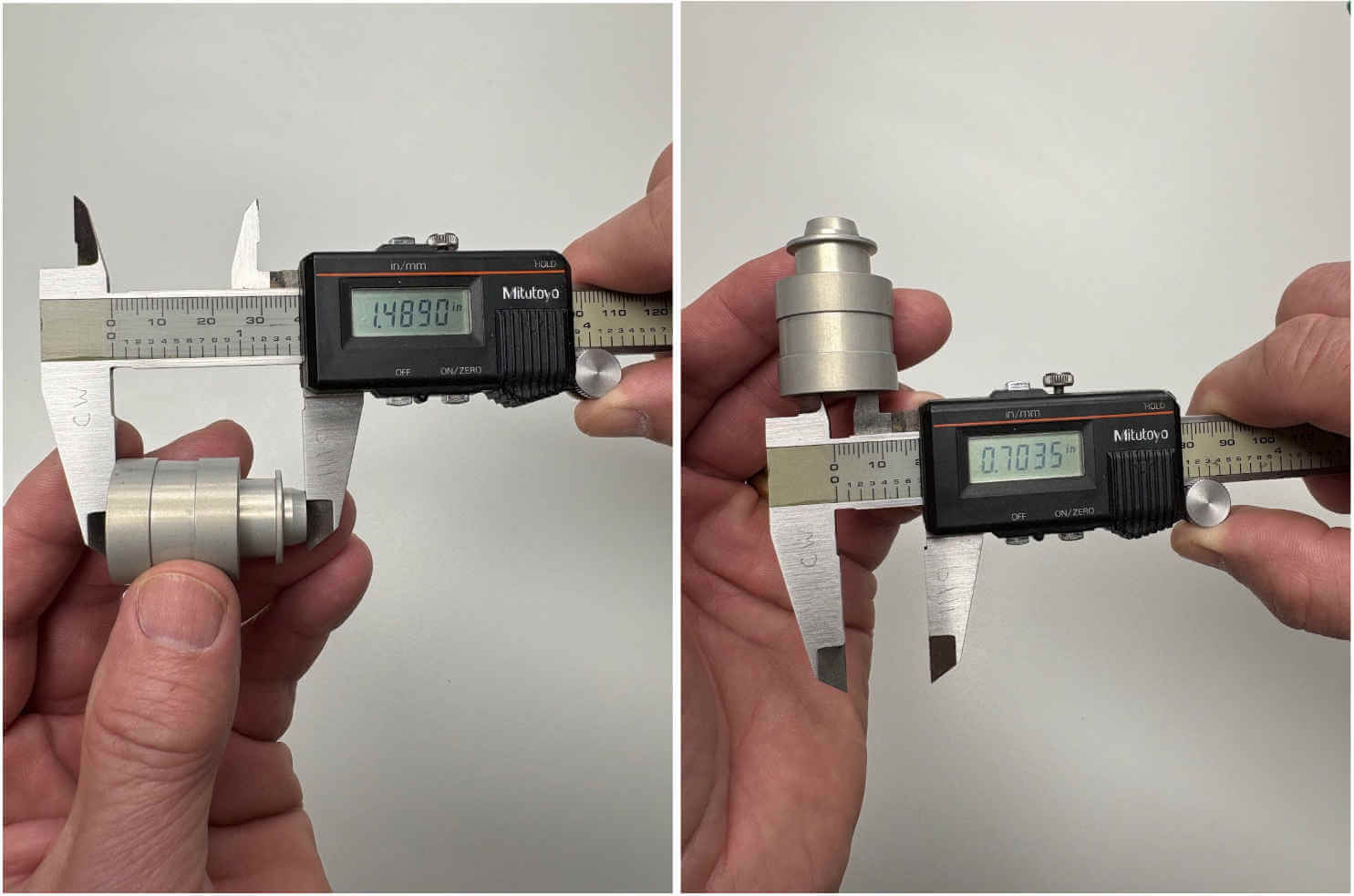

How Caliper Accuracy Impacts Precision Machining

At Topcraft Precision, we know that great machining starts with great measurement. The humble caliper might not be the flashiest tool on the shop floor, but it’s one of the most important. Without dependable measurements, even the best machining processes can fall short. Why Calipers Matter in Machining A caliper is a machinist’s best friend when it comes to checking